SAFETY TIPS

What are the points to remember about the Rubber Tubing ?

- It must be of approved quality (ISI mark).

- It should be as short as possible. The maximum length should be about 1.5 metres.

- It should be easily accessible for inspection.

- Keep it away from heat and fire.

- Push it so as to cover the full length of the nozzle.

- Make sure it does not get heated by the burner or is looped or twisted.

- Clean it with a wet cloth only. Don’t use soap to ease the tube over the nozzle.

- Replace tubing every 2 years, if not earlier.

- Do not cover rubber tubing with any other object or sleeve.

The Pressure Regulator is very important too.

The purpose of this device is to regulate the gas pressure in the cylinder by connecting to the cylinder valve outlet. It ensures that a constant and safe gas pressure is supplied to the hot plate for optimal performance.

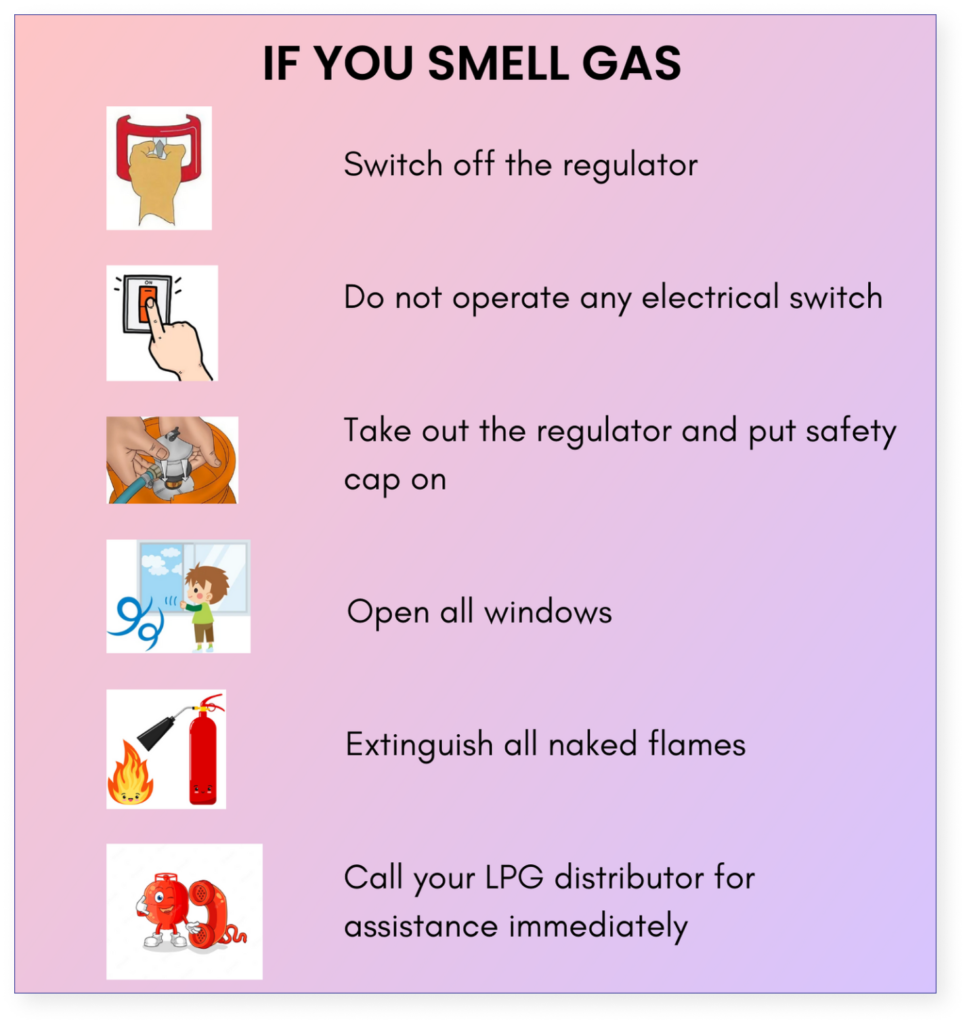

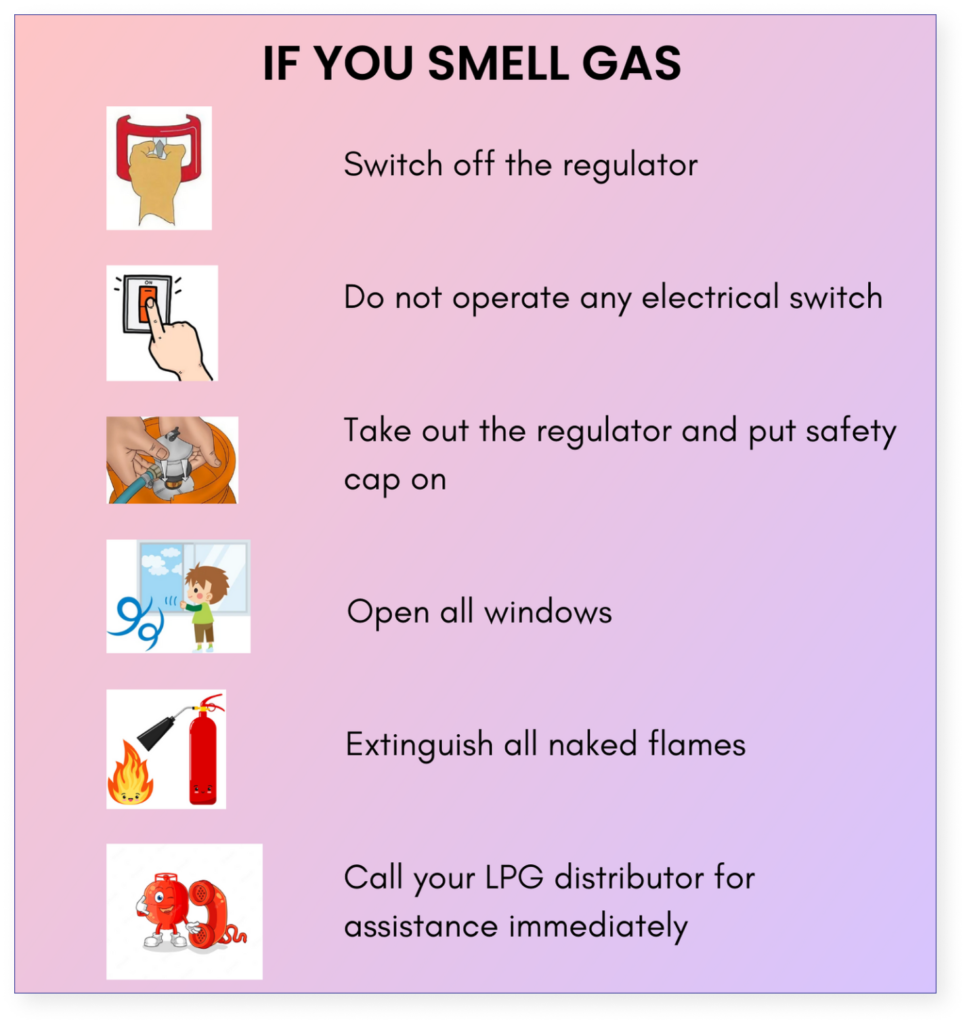

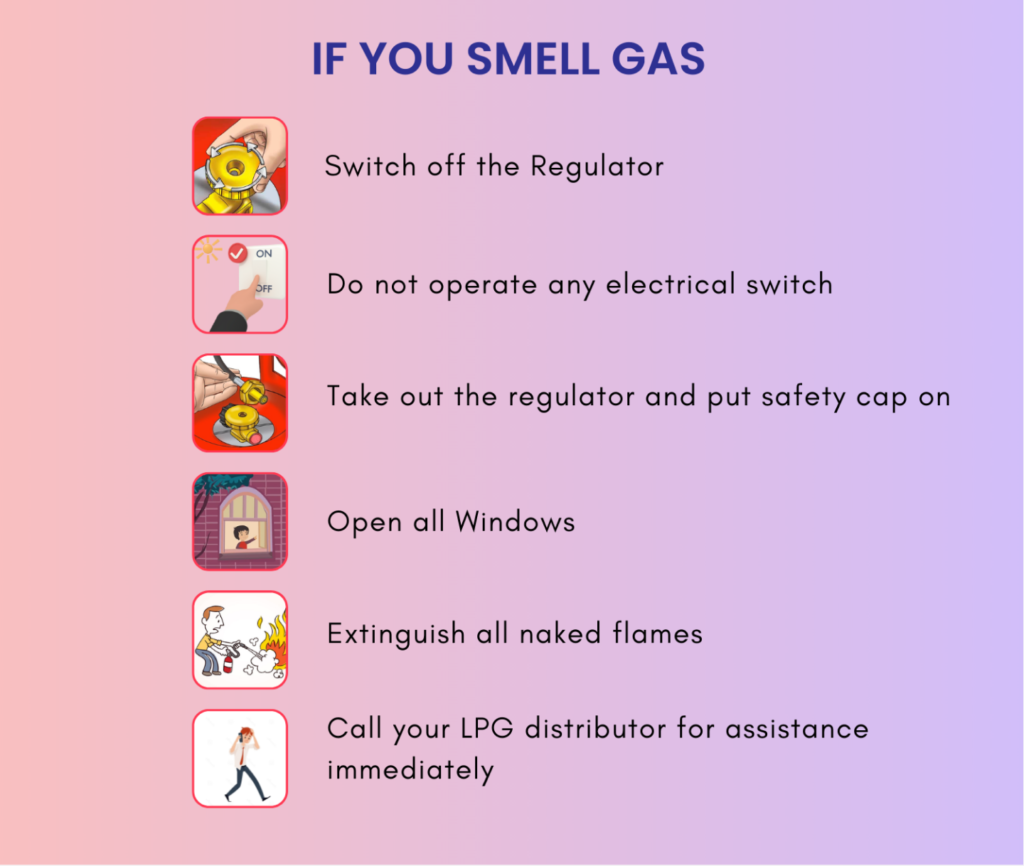

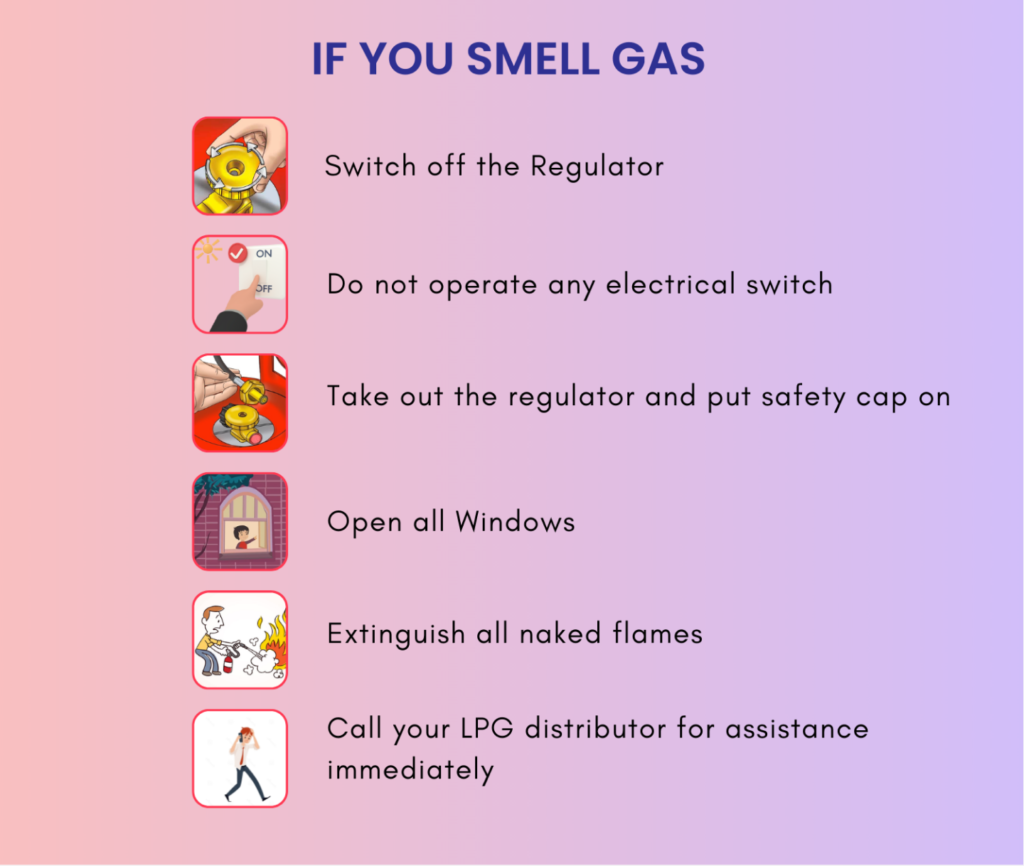

- If you smell gas

- Disconnecting the empty cylinder

- Connecting the filled cylinder

- To light the burners

- Safety goes a long way.

- Good habits for your safety.

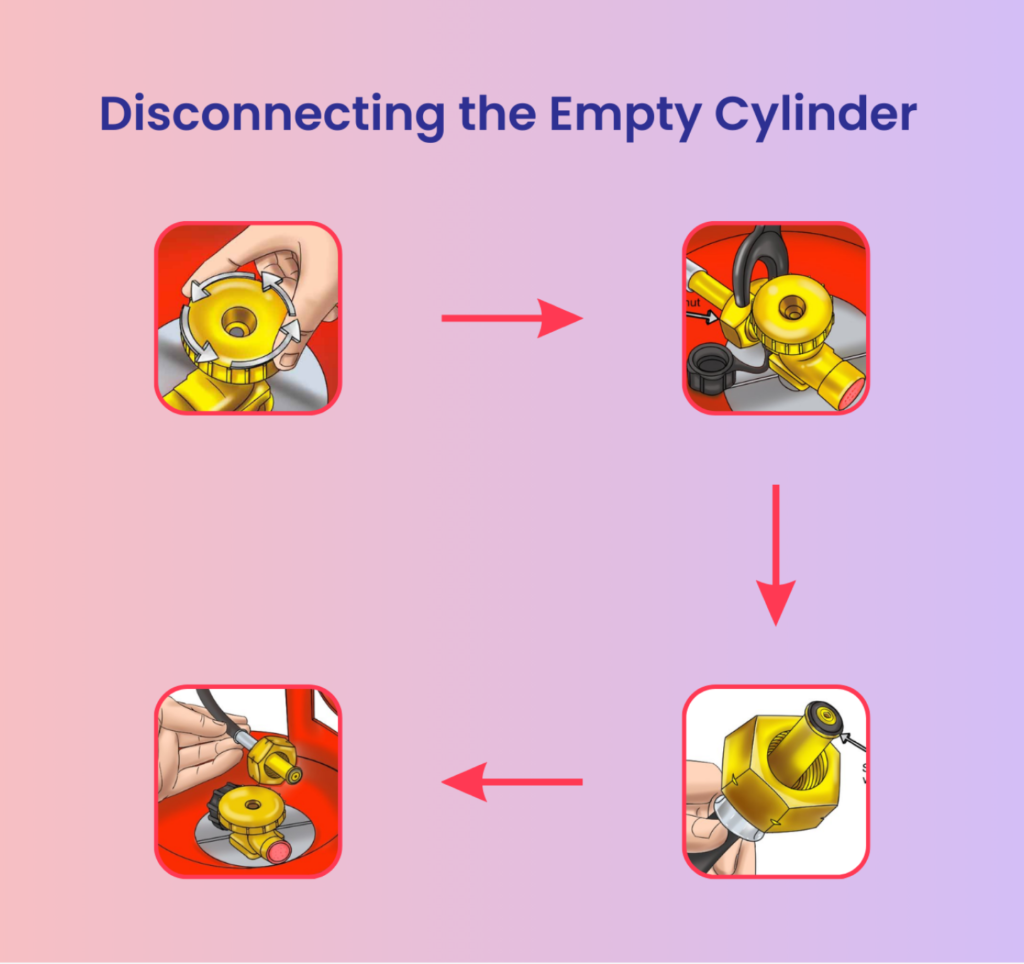

01. Disconnecting the empty cylinder

- Do not operate electrical switches.

- Disconnecting the empty cylinder

- Ensure that the stove knobs are in the OFF position.

- Do not light a matchstick even to detect the leakage of LPG.

- Switch off the pressure regulator by turning the knob clockwise to the off position.

- Open all doors and windows.

- An experienced person can detach the regulator. Fix the safety cap on the valve.

- If the smell persists, call your HP Gas distributor during office hours. For emergencies after office hours or on holidays, please call your nearest emergency service cell.

02. Disconnecting the empty cylinder

- Close all the taps on the cooking stove.

- Put out all the flames and fires, including incense sticks, candles, and the pooja lamp, in the kitchen and adjoining rooms.

- Put out all the flames and fires, including incense sticks, candles, and the pooja lamp, in the kitchen and adjoining rooms.

- Turn the switch knob of the regulator from the ON position to the OFF position.

- Place the delrin (plastic) safety cap on the valve of the cylinder. Press the cap firmly down until a distinct click is heard. Now the empty cylinder can be removed.

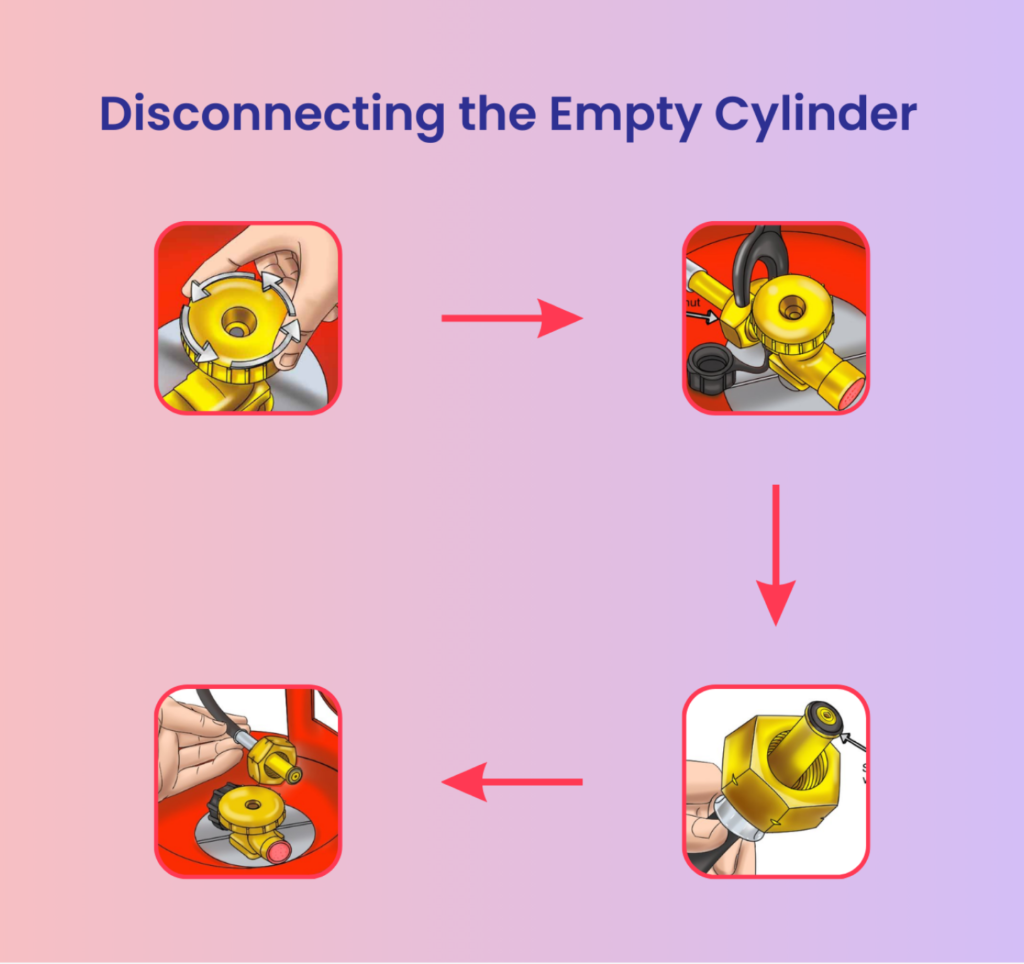

03. Connecting the Filled Cylinder

- To remove the safety cap, press it down, pull the cord, and, keeping it pulled, lift the cap off the valve of the cylinder.

- Check whether the sealing ring is in place inside the cylinder valve by feeling it with your little finger. Do not use the cylinder if the ring is missing; put back the safety cap and contact your distributor for a replacement cylinder.

- To mount the regulator on the filled cylinder, carry out the following steps

- Ensure the switch knob of the regulator is in the OFF position.

- Grip the regulator and pull up the plastic blush.

- Place the regulator vertically on the valve and press it down till its edge touches the hexagon of the valve on the cylinder with a gentle swivel. Release the black plastic bush and then press it down. (You may hear a click sound.)

- The pressure regulator is now locked on the cylinder.

04. To light the burners

- Turn the switch knob of the regulator anti-clockwise till it is in the ON position. Hold a lighted matchstick near the burner head of the stove and turn the knob of the stove to the ON position.

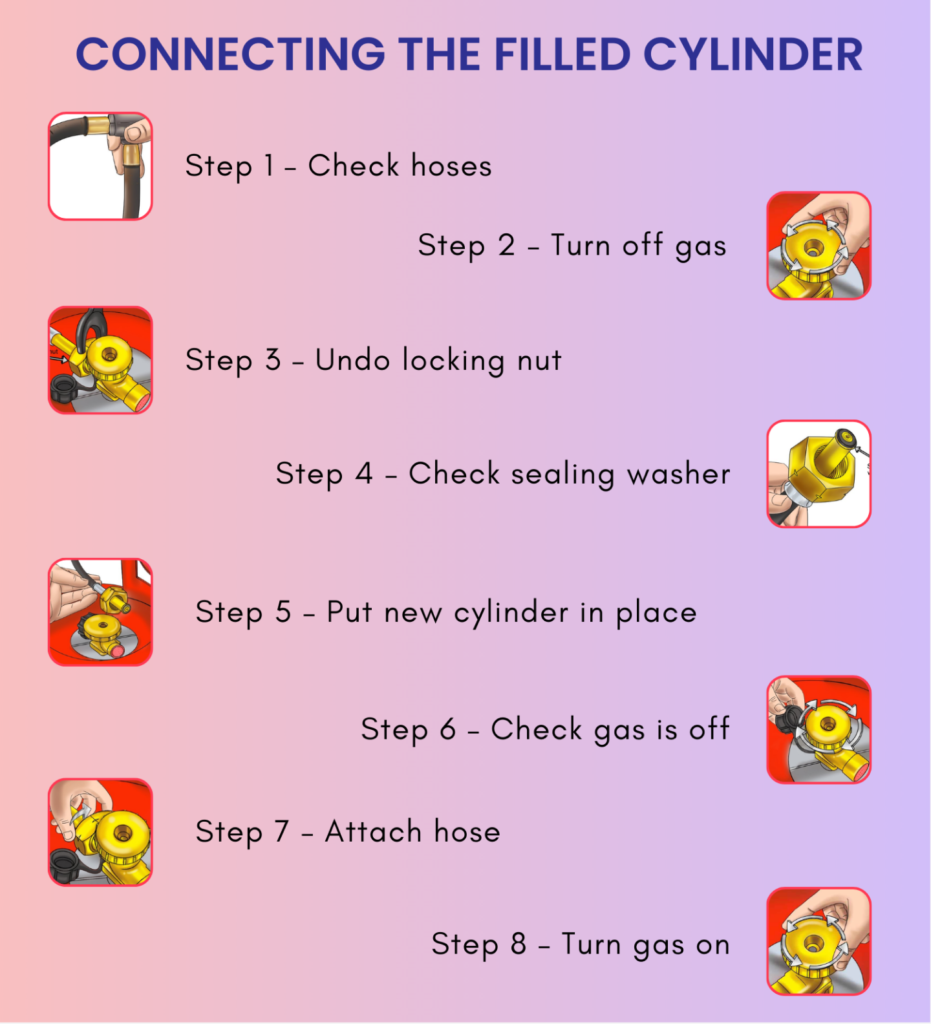

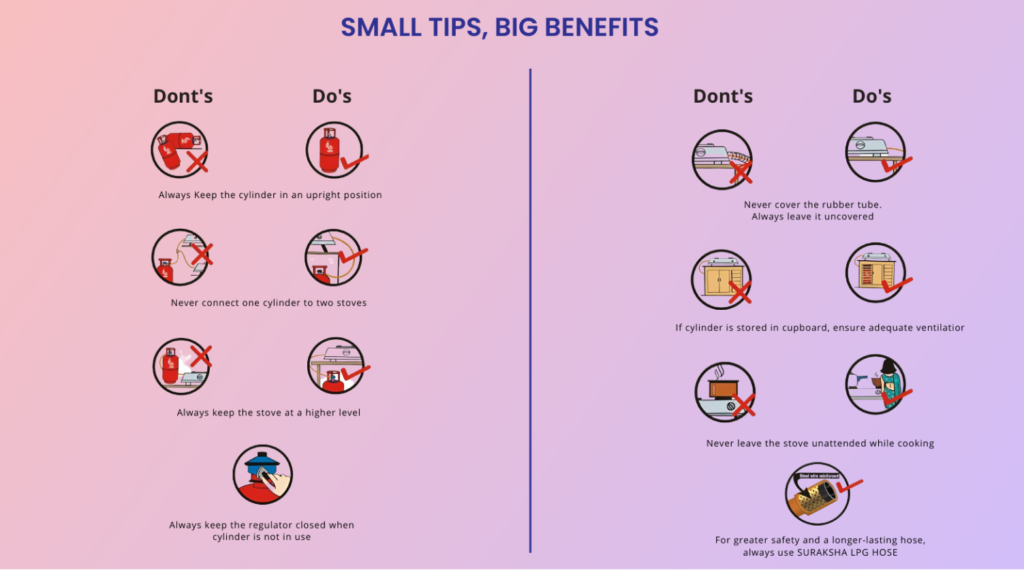

05. Safety goes a long way.

- Do not wear nylon garments or similar fabrics when cooking.

- Never leave the cooking appliance unattended when in use.

- Never try to repair, adjust, or inspect any part of the HP gas installation or allow fake mechanics to do so. Allow authorised mechanics to inspect the installation once every two years.

- Do not use long curtains on windows if your cooking appliance is near them. They can blow over the burner and catch fire.

- Insist on a redelivery check of the refill cylinder at the time of its delivery.

- Do not install the cooking appliance on the floor. Do not use a wooden table without an asbestos sheet over it.

- HP gas should never be used in a poorly ventilated room.

- Never install a HP gas cylinder below ground level or in cellars or basements.

- No other heating device (like an electric oven or a kerosene stove) should be placed within one metre of a HP gas appliance.

- Do not use any cover on the rubber tube, rubber tube T-joint connection, or trolley for the cylinder in your HP Gas installation.

- Never leave the regulator in the ON position after cooking is over or during the night.

- Always smell for leakage of LPG before lighting the stove.

- Never use the rubber tube if it has cracks or is more than 2 years old.

06.Good habits for your safety

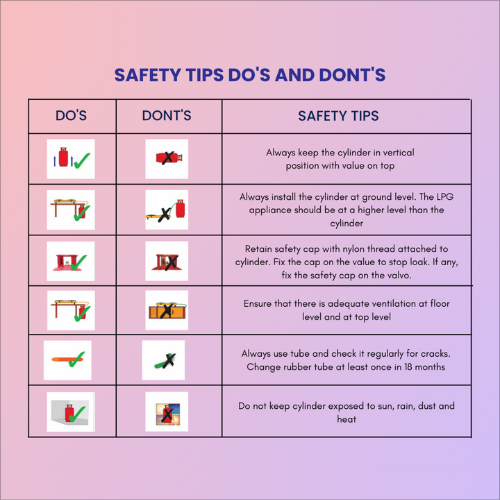

- Always keep the cylinders in a vertical position with the valve on top.

- Cylinders must be installed at ground level and never below ground level or in cellars or basements.

- Avoid storing combustible articles close to the cylinder and LPG installation.

- Always keep the safety or security cap tied with the top ring stay plate.

- Use BIS-approved rubber tubes and hot plates or appliances.

- Keep the kitchen well ventilated and clean to avoid rats, cockroaches, etc.

- Ensure that the appliance is at least one metre away from electric wiring, switches, or plug points.

STORAGE & HANDLING OF LUBRICANTS

A planned storage and handling system will ensure the following advantages:

- Proper product quality guarantee

- Elimination of product contamination

- Elimination of incorrect grades and mixing of products

- Reduced leakage and other losses

Ideal Storage conditions :

- Easily accessible

- Well-ventilated and well-lit

- Spacious

- Away from heat sources

- Well-protected from rains

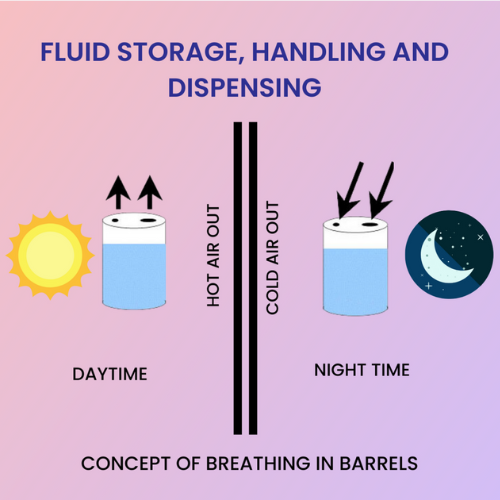

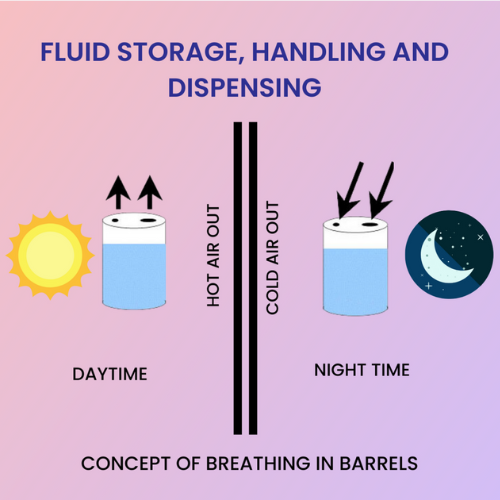

Issues with outdoor storage:

- Brand names may be obliterated.

- Drums may rust and result in leaks.

- Drums are prone to contamination.

- Away from heat sources

- Well-protected from rains

Lubricants can be stored in the ways mentioned below for better results:

- Sealed drums should be kept grade-wise separately.

- Keep sufficient space between rows and rums for easy movement.

- Keep grease drums upright to avoid spillage.

- Move out drums on a first in, first out basis. Proper handling and dispensing of lubricants is equally important as proper storage.

DISPENSING OF LUBRICANTS

- The dispensing system for a plant layout involving long distances between storehouses and different sections requires proper planning to ensure quick and better transportation. A few guidelines, as given below, would be helpful to achieve this very easily.

- Issue drums to sections for frequent consumption to avoid transportation.

- Fit barrel pumps or faucets to drums for quick dispensing without spillage

- Keep M.S. trays below each faucet to collect spillage.

- Use a colour code scheme to avoid incorrect issues with lubricants.

- Use containers with tight-fitting lids for transportation.

- Use metallic paddles instead of hand or wooden sticks to withdraw grease

- Issue grease drums on a "First In, First Out" basis.

- Use up the product within a year of manufacture.

HANDLING

- It is preferable to use forklifts or chain hoists for stacking drums in stores or moving drums from stores to departments or sections. If this is not possible, tyres or wooden planks should be used while unloading the drums. Trolleys may be used for transporting drums instead of rolling them.